Engineering Design

What makes us the premier design firm in the MENA region and Sub-Saharan Africa?

The answer comes in one all-encompassing word: Versatility.

Versatility is what allows us to meet the requirements of diverse projects and respond to the needs of different individuals. Versatility is what allows us to innovate and adapt wherever we are in the world. Versatility is also how we always manage to reconcile cost-effectiveness with great quality.

Our extensive range of engineering and design services plays a great role in enhancing this versatility as well:

ECG’s engineering services cover MEP, infrastructure, transportation and process engineering, in conjunction with a range of supplementary engineering services. These include civil and environmental engineering, together with fire protection, lighting, communications, security, and building management systems.

Our design services, on the other hand, cover Front-End Engineering & Design (FEED), Conceptual Design, Preliminary Design, Basis of Design Reports (BODRs), Schematic Design, Design Development, Detailed Design, Design Optimization, Construction Documents, Value Engineering and Computer Simulations.

see projects related

Architectural Design

We will admit we are perfectionists. When it comes to architectural design, we want to be innovative, functional, beautiful, environmentally friendly, and above all, we want to leave a legacy for the generations to come. We also want to bring all that to every possible structure. Whether it be a bridge or a highway, an exterior or an interior, we want it to shine.

Although this perfectionism keeps us up all night, it also pays off. We are very proud of our contributions to some of the most prestigious projects in the region: From landmark high-rises and mega residential compounds, to business parks and LEED compliant buildings, and from acoustics and vertical transportation to conveyor systems and much more.

see projects related

Alexandria Wastewater Program (Phase I)

Alexandria’s sewer and storm-water networks, pumping stations, and treatment plants were old and deteriorating.

Sewer breaks were frequent and untreated sewage flooded over the city streets. Raw sewage was directly discharged into the Mediterranean Sea, polluting both the sea and the beaches. To address such critical situation, a phased implementation plan was initiated by the Government of Egypt and funded by the USAID to improve and expand Alexandria’s wastewater system.

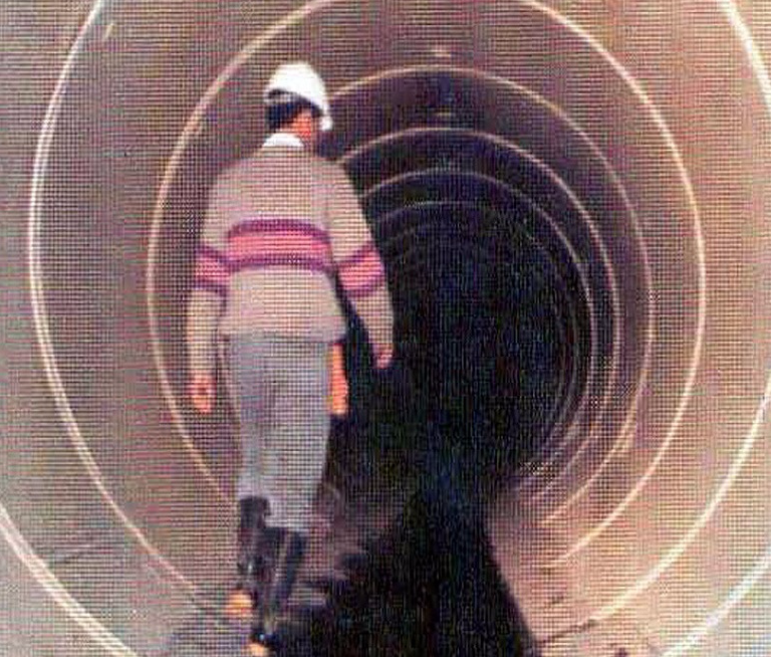

ECG, in joint venture with two global US consultants Metcalf & Eddy and CH2MHill, designed and supervised the construction of pumping stations, two major treatment plants, two bored tunnels of 21 km length and up to 1,200 mm diameter each, under-crossings, force mains, collectors, sewer networks, sea outfalls, drain improvement, sludge disposal facilities, and mechanical sludge dewatering facilities.

From 1980 to 1995, the following sub-projects were implemented under the Wastewater Upgrade Program (Phase I):

- Review and update of Alexandria Wastewater Master Plan up to the year 2000. This review included in-depth feasibility study for re-use of treated wastewater to develop an agricultural area of 70,000 acres. The review also considered the disposal of primary treated wastewater effluent through sea outfalls.

- Field investigations included comprehensive soil investigations and survey programs. The survey works comprised land survey and aerial photography for 750 km2 . Works also comprised ground control of horizontal and vertical stations tied to the national second degree network and mapping in scales of 1:1000 ,1:500 and 1:5000.

- Abu Qir Force Main: 1.2 km long and 450 mm diameter.

- Sidi Bishr Force Main: 1.3 km long and 1,000 to 1,200 mm diameter.

- Smouha Force Main: 1.7 km long and 600 to 1,800 mm diameter.

- East Zone Force Main: 5.5 km long, double line and 1,500 to 1,800 mm diameter.

- Smouha Collectors: gravity sewers 6.1 km long and 200 to 2,750 mm diameter with associated manholes.

- Sidi Bishr Collectors: gravity sewers 4.3 km long and 1,200 to 1,500 mm diameter with associated manholes.

- Abu Qir Collectors: gravity sewers 6.7 km long and 300 to 1,500 mm diameter with associated manholes.

- Smouha Sewage Networks: gravity sewers, 11 km long and 200 to 900 mm diameter with associated manholes.

- Abu Qir Sewage Networks: gravity sewers, 32 km long and 200 to 800 mm diameter with associated manholes.

- ElSiouf ElKeblia and Hagar Elnawatiya Sewage Networks: gravity sewers, 8 km long and 200 to 800 mm diameter with associated manholes.

- Hydrodrome Drain Improvement including: new transition structures and miscellaneous appurtenances.

- Smouha Drain Improvement: by adding new sewers, manholes, junction boxes, transition structures and miscellaneous appurtenances.

- New East Zone Pumping Station: 21 m deep, with maximum lifting capacity of 600,000 m3/day. For dry construction purposes, a 20 m long steel sheet piles were driven to form circular cofferdam with 54 m diameter.

- New Smouha Pumping Station: 17 m deep, with maximum lifting capacity of 340,000 m3/day. For dry construction purposes, a 20 m long steel sheet piles were driven to form a circular cofferdam with 45 m diameter. An intensive dewatering system was designed and implemented during the construction period.

- New Sidi Bishr Pumping Station: 13 m deep, with maximum lifting capacity of 165,000 m3/day.

- New Maamoura Pumping Station: 12 m deep, with maximum lifting capacity of 100,000 m3/day. For dry construction purposes, a 20 m long steel sheet piles were driven to form a circular cofferdam with 45 m diameter. An intensive dewatering system was designed and implemented during the construction period.

- Upgrading the East Treatment Plant including: new headwork structures, a new flow split structure, demolishing existing clarifiers and constructing eight (8) new ones, eight (8) new pumping stations and a new on-site employee housing. (further description of the project is included in the subsequent sheets).

- Upgrading the West Treatment Plant including: new influent pumping station (955,500 m3/day), new headworks, new primary sedimentation tanks, yard piping (200 mm to 2,750 mm diameter), modifications to existing building and new on-site employee housing (further description of the project is included in the subsequent sheets).

- ElSiouf ElKeblia and West Zone Tunnels: 21 km long of 1,200 mm diameter each. Tunneling execution was either by using tunneling boring machine or by shield and jacking equipment according to soil characteristics. All manholes were constructed by sinking caisson method.

- Smouha and East Zone Undercrossings including:

- – Smouha force main undercrossings with two highways and a double-track branch line railroad (by jacking method) and with a canal (by tunnel boring machine).

- East Zone force main undercrossings with two highways and a doubletrack main line railroad (by jacking method) and with a canal (by tunnel boring machine).

- Smouha drain undercrossing with two highways and a double track branch line railroad (by jacking method).

- Sludge Disposal Facilities: for the disposal of sludge, grit, scum and screenings of the treatment plants.

- Mechanical Sludge Dewatering Facilities: including new sludge equalization tanks; new dewatering pump station with equalization tank; blower and sludge transfer pumps; new dewatering building with sludge feed pumps; belt filter passing polymer system and sludge cake conveyors.

UASB Sanhour Wastewater Treatment Plant (Phases III & V)

ECG was involved in implementing a pioneering Upflow Anaerobic Sludge Blanket (UASB) system in order to expand and upgrade the existing Sanhour wastewater treatment plant and increase its capacity from – 1,750

14,000 m3 / day.

Caltex Lube Oil Blending Plant

Premised on a plot area of 26,000 m2, the 7 million dollar lube oil blending facility produces 23,000 tons of automotive, industrial and marine oil of different categories. The plant consists mainly of 3,200 m2 base oil storage area surrounded by a bund wall of soil embankment covered by a bituminous sand layer with eight steel tanks of 300 m3 to 1,000 m3 capacity; 2,400 m2 steel-structured blend center / warehouse building comprises the blending area with five (20 m3) heated tanks (blending kettles) and filling machines; 600 m2 mezzanine floor for storage of empty containers and cartons as well as finished product storage area of 780 m2; in addition to a two-storey building for offices and laboratory; 300 m2 finished product storage area of reinforced concrete bund wall including two steel tanks of 50 m3 to 100 m3 capacity; utility building where the plant boiler and air compressor are located; and 3,000 m2 of uncovered storage area for the storage of drummed additives and products in addition to an extra area for the plant future expansion.

ECG also designed and constructed the siteinfrastructure including roads, fire protection system, roads and plant fences.

see projects related